Add to Cart

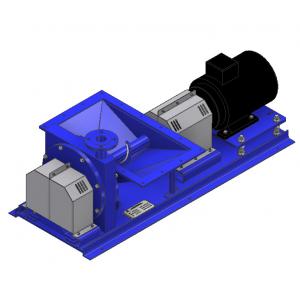

Transport The Final Oil Shipping Weight Is 480kg Dry Pump Oil Pump

Suction oil pressure The oil suction and pressure of the fuel injection pump are completed by the reciprocating movement of the plunger in the plunger sleeve. When the plunger is in the lower position, the two oil holes on the plunger sleeve are opened, the inner cavity of the plunger sleeve is communicated with the oil passage in the pump body, and fuel is quickly filled into the oil chamber. When the cam hits the roller of the roller body, the plunger rises. Move upward from the beginning of the plunger until the oil hole is blocked by the upper end of the plunger. During this period of time, due to the movement of the plunger, the fuel is squeezed out of the oil chamber and flows to the oil passage. So this period of lift is called pre-stroke. When the plunger blocks the oil hole, the oil pressure process begins. As the plunger moves upward, the oil pressure in the oil chamber rises sharply. When the pressure exceeds the spring force of the delivery valve and the upper oil pressure, the delivery valve is opened, and the fuel is pressed into the fuel pipe and sent to the fuel injector. The moment when the oil inlet hole on the plunger sleeve is completely blocked by the upper end surface of the plunger is called the theoretical oil supply starting point. When the plunger continues to move upwards, the oil supply continues, and the oil pressure process continues until the spiral bevel on the plunger lets the plunger sleeve return to the oil hole. When the oil hole is opened, high-pressure oil flows through the oil chamber. The longitudinal groove on the plunger and the oil return hole on the plunger sleeve flow back to the oil passage in the pump body. At this time, the oil pressure in the plunger sleeve oil chamber drops rapidly, the oil outlet valve drops back to the valve seat under the action of the oil pressure in the spring and the high-pressure oil pipe, and the fuel injector stops fuel injection immediately. At this time, although the plunger continues to move upward, the fuel supply has stopped. The time when the oil return hole on the plunger sleeve is opened by the bevel of the plunger is called the theoretical oil supply end point. During the whole process of the upward movement of the plunger, only the middle section of the stroke is the oil pressing process, and this stroke is called the effective stroke of the plunger.

| Design flow :5m³/h | 5m³/h |

| design lift | 15M |

| Conveying medium: | oil containing certain solids (solid content ≤ 30%) |

| Motor Power | 4kw |

| shaft brand | FAG |

| motor brand | Simens |

| shipping size | 1400*710*550 |

| shipping weight | 480kg |